Automation and Integration

Automated and integrated systems to optimize performance and maximize efficiency in your industrial operation.

Efficiency and Performance, That’s How Our Company Operates!

We can design a software-controlled automated system from scratch, modify your existing controls, or create a new control system according to your needs.

PLC Programming

Programmable Logic Controller

Enables the creation of a customized control program for a specific industrial application. The program manages the operation of the machine or process, monitoring sensor inputs and making decisions based on predefined algorithms. This helps increase process efficiency, reduce human errors, and minimize failures.

HMI Programming

Human-Machine Interface

Creation of the graphical interface that allows operators to monitor and control the industrial process. The HMI screens display real-time information, such as production line speed or storage tank temperature. Operators can also use the HMI to make adjustments in the process, such as changing machine speed or adjusting furnace temperature.

HMI Programming

Human-Machine Interface

Creation of the graphical interface that allows operators to monitor and control the industrial process. The HMI screens display real-time information, such as production line speed or storage tank temperature. Operators can also use the HMI to make adjustments in the process, such as changing machine speed or adjusting furnace temperature.

Customer-Specification Driven Control Design

Control systems that meet specific needs regarding what the system should do, how it should operate, and what features it should have. The development process starts with analyzing client requirements, followed by system design, implementation, testing, and validation.

Meeting Specific Needs

A more effective and tailored control system for the client.

Operational Efficiency

Automation of repetitive processes, reducing the need for human intervention.

Safety

Ensuring accidents avoidance and safe system operation.

User-Friendliness

Designing a customized and user-friendly interface for ease of use.

Flexibility

Adaptable, allowing the client to make changes or updates in the future if necessary.

Reliability

Minimizing downtime and ensuring the system is always operational.

Control Engineering Services

Precise and reliable control systems to operate with high performance and safety.

Integration and Programming of Industrial Robots

We automate entire production processes to enhance the efficiency and productivity of your industrial operation. Performing repetitive tasks with greater precision and speed, robots can operate for extended periods, reducing operational costs, errors, and workplace accidents.

Supervisory Control and Data Acquisition Systems

Monitor and control your industrial processes in real-time! Data acquisition systems are used to collect information from sensors and other devices, transmitting it to a computer or control system. This system then processes the data and sends commands to actuators to adjust the process in real-time.

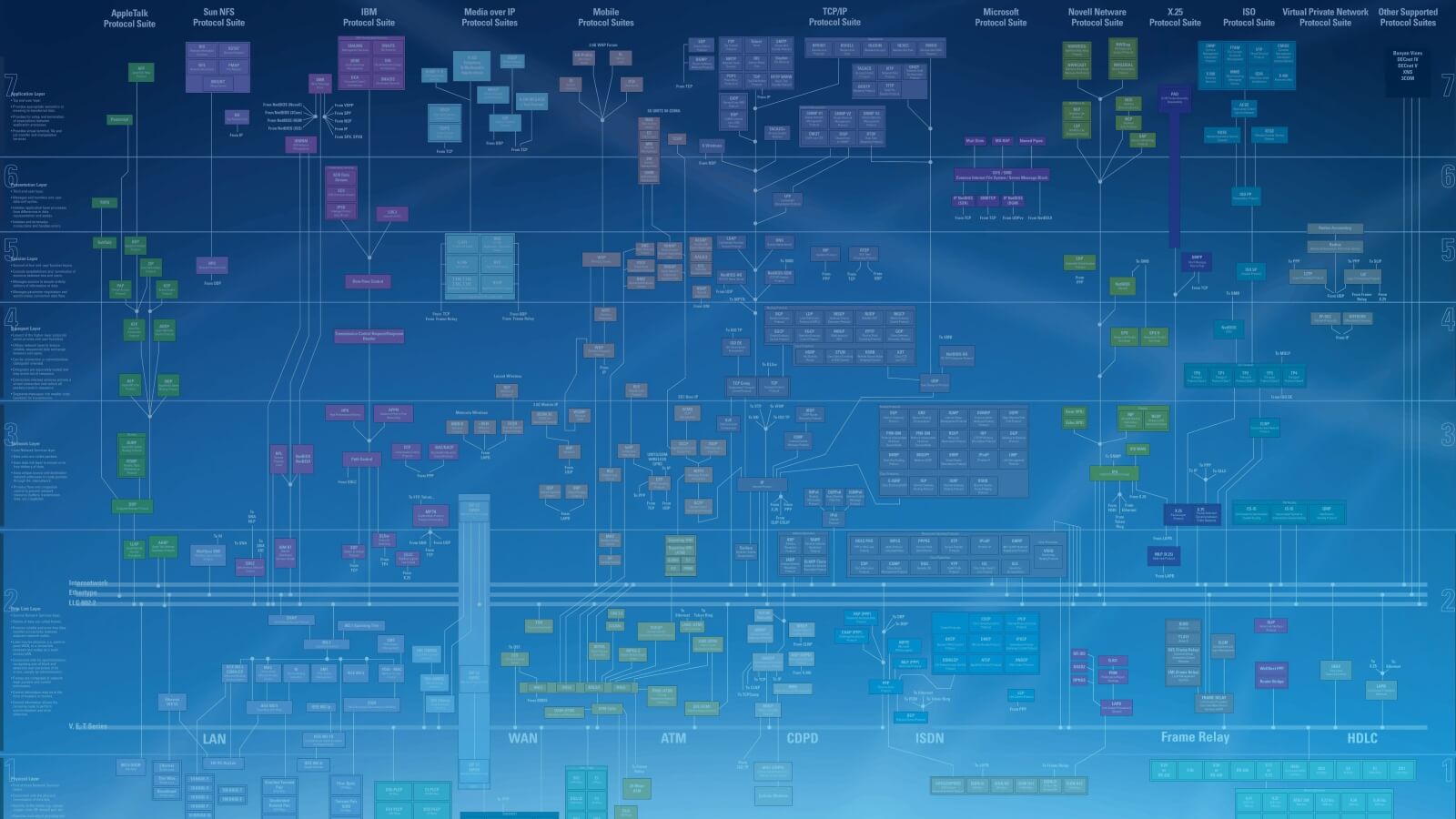

Communication Protocol Design

Essential for ensuring interoperability and effective communication among different equipment and systems in an industrial plant. It enhances reliability, efficiency, safety, reduces maintenance costs, and offers more flexibility in your industrial process.

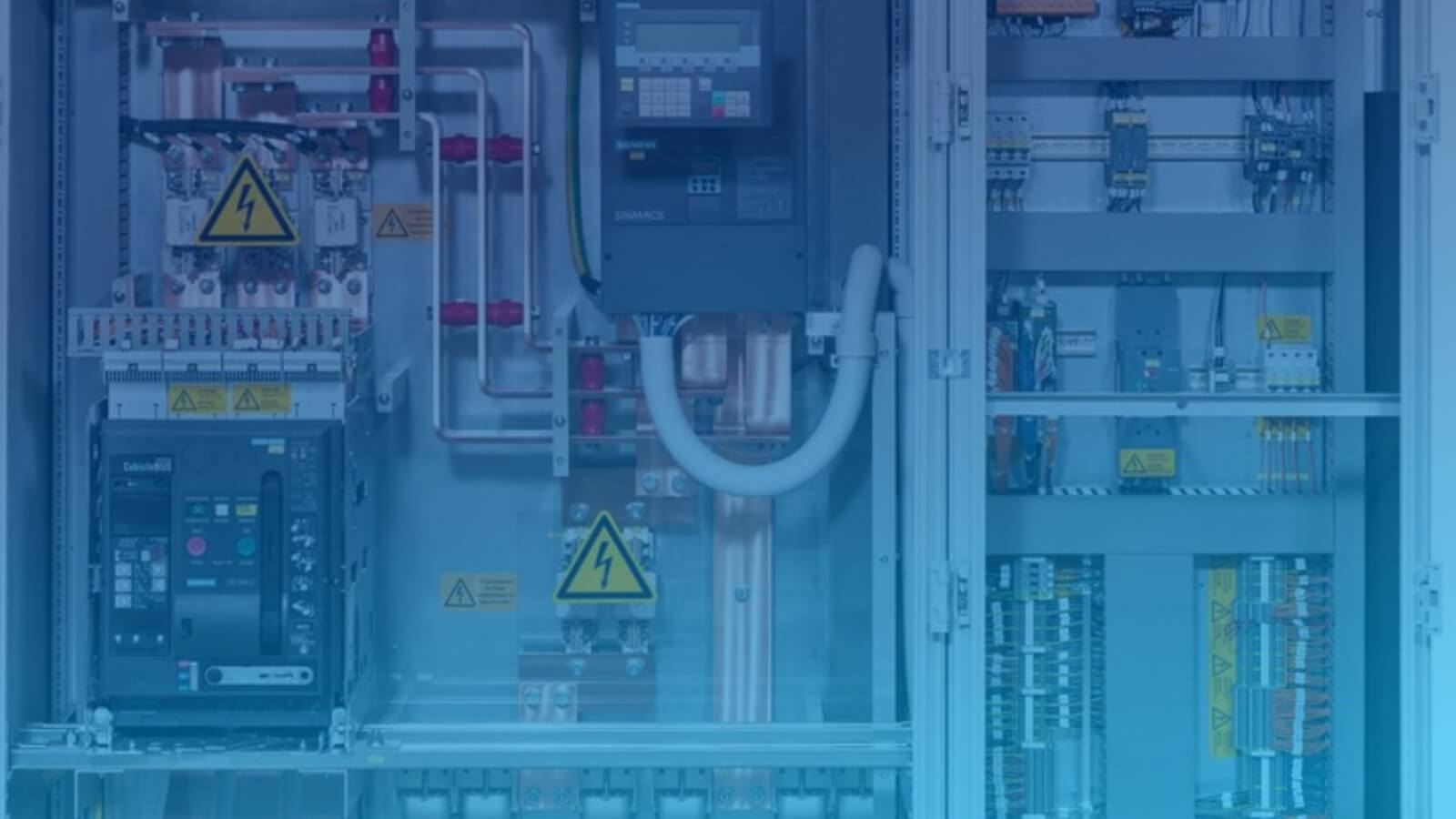

Integration between Drive and Control Technologies

We develop systems and devices to control the operation of equipment and processes across a wide range of industries and applications, enabling precise and effective operation of complex processes.

Machine Commissioning and Testing

Critical processes to ensure machines function correctly and safely. Commissioning involves verifying and testing all machine parts, including electrical, mechanical, and hydraulic components, to ensure everything is in order and the machine is ready for use.

Automation Program Improvement, Risk Analysis, and Implementation of Safety Measures

Critical for ensuring automated systems are safe and reliable. Evaluating existing programs, implementing safety measures, providing training, monitoring, and regular updates ensure the continuous optimization of these systems.

Optimize Your Production, Maximize Your Results

Rely on our team’s expertise and technology to implement customized and efficient solutions, ensuring faster and more precise results.

Want to learn more about our services?

Count on us!

Interested in how Spinula can assist with your company’s automation processes? Fill out the form to start a conversation!

Address Brazil

Alameda Júpiter, 855

American Park Empresarial

Indaiatuba/SP - CEP 13347-397

Address United States

1226 E McDevitt Ave, Jackson, MI 49203, United States